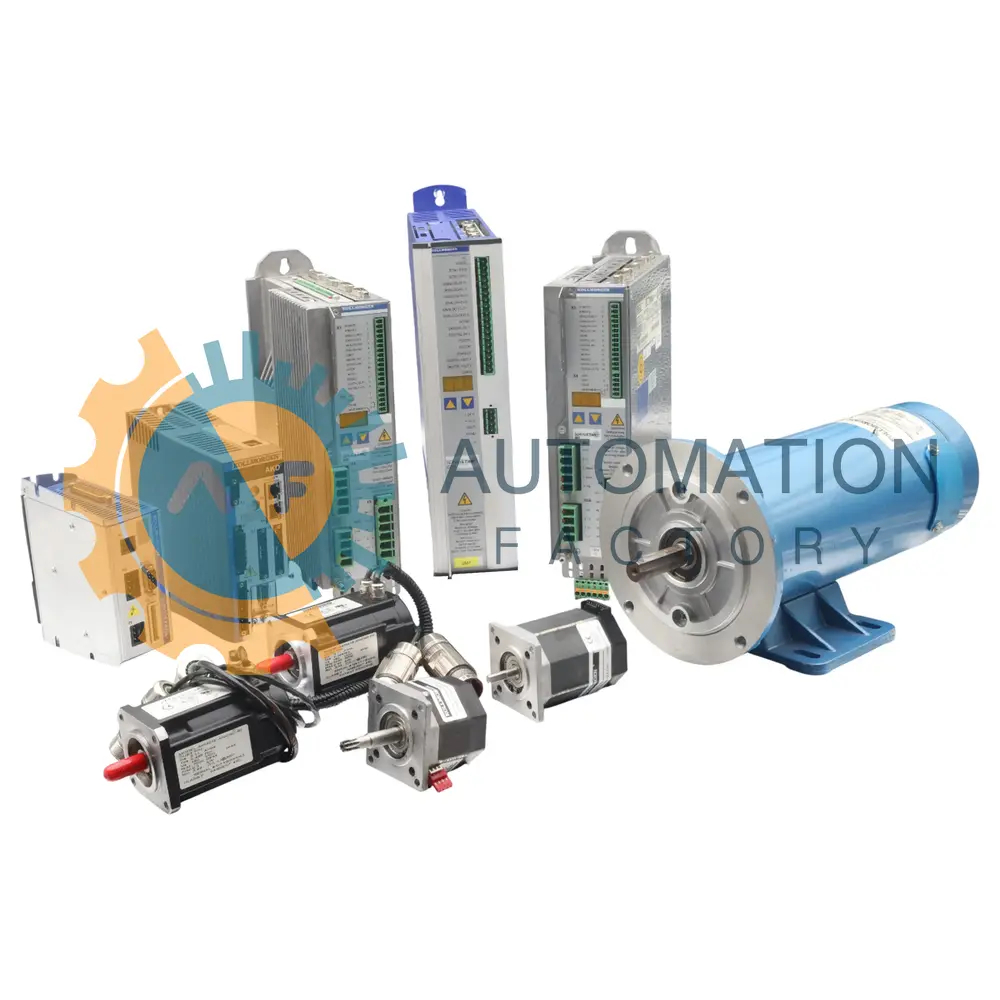

S61001 by Kollmorgen

Get a Quote for S61001

Request a quote or call us now at 1-919-443-0207 !

We respect your privacy. Your information is safe and will never be shared.

Secure Online

Checkout

Free Ground

Shipping

One Year

Warranty

Technical Specifications

10A rms

AS option

S600 Servo Drive

230...480V

High

10 mm

HRC 22

50 mm

Stainless Steel

-40°C to 400°C

700 MPa

1.0 mm

M6

520 MPa

Contact Us

1620 Old Apex Road, Cary, NC 27513, USA

Toll Free: 1-888-551-3082

International: 1-919-443-0207

Fax: 1-919-867-6204

Email: sales@wakeindustrial.com

Need Assistance?

Our team is here to help you find the right part for your needs.